| Alloy | Temper |

| 6005 ,6005A,6061,6082 | T4,T5,T6 |

| Alloy | Chemical component(%) | ||||||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Zr | Other | Al | |||

| Each | Total | ||||||||||||

| 6005 | 0.6-0.9 | ≤0.35 | ≤0.10 | ≤0.10 | 0.40-0.6 | ≤0.10 | ≤0.10 | - | - | ≤0.10 | ≤0.05 | ≤0.15 | Remain |

| 6005A | 0.5-0.9 | ≤0.35 | ≤0.30 | ≤0.50 | 0.40-0.7 | ≤0.30 | ≤0.20 | Mn+Cr:0.12-0.50 | ≤0.10 | - | ≤0.05 | ≤0.15 | Remain |

| 6061 | 0.40-0.8 | ≤0.7 | 0.15-0.40 | ≤0.15 | 0.8-1.2 | 0.04-0.35 | ≤0.25 | - | ≤0.15 | - | ≤0.05 | ≤0.15 | Remain |

| 6082 |

0.7- 1.3 |

≤0.50 | ≤0.10 | 0.40-1.0 | 0.6-1.2 | ≤0.25 | ≤0.20 | - | ≤0.10 | - | ≤0.05 | ≤0.15 | Remain |

| Level of deviation |

Allowable deviation of the following length or width. mm |

|||||||||

|

≤ 120 |

> 120- 400 |

> 400- 1000 |

> 1000- 2000 |

> 2000- 4000 |

> 4000- 8000 |

> 8000- 12000 |

> 12000- 16000 |

> 16000- 20000 |

> 20000 |

|

| A | +/-1 | +/-1 | +/-2 | +/-3 | +/-4 | +/-5 | +/-6 | +/-7 | +/-8 | +/-9 |

| B | +/-2 | +/-2 | +/-3 | +/-4 | +/-6 | +/-8 | +/-10 | +/-12 | +/-14 | +/-16 |

| C | +/-3 | +/-4 | +/-6 | +/-8 | +/-11 | +/-14 | +/-18 | +/-21 | +/-24 | +/-27 |

| D | +/-4 | +/-7 | +/-9 | +/-12 | +/-16 | +/-21 | +/-27 | +/-32 | +/-36 | +/-40 |

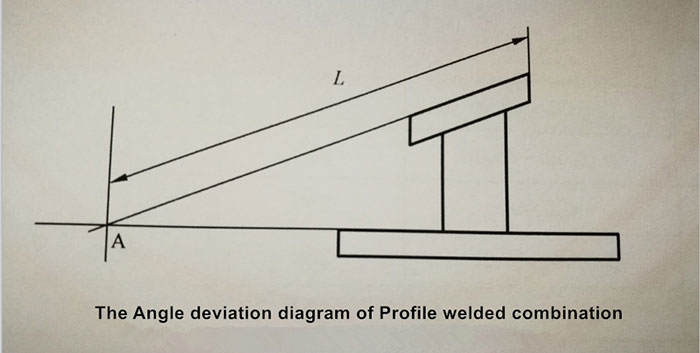

| Level of deviation | Below reference dimension L corresponding angle allowable deviation. | ||

| ≤ 400mm | >400mm-1000mm | >1000mm | |

| A | +/-0.33° | +/-0.25° | +/-0.17° |

| B | +/-0.75° | +/-0.50° | +/-0.33° |

| C | +/-1.00° | +/-0.75° | +/-0.50° |

| D | +/-1.50° | +/-1.25° | +/-1.00° |

|

Level of deviation |

The below long side of Profile welded combination corresponding straightness, flatness,or short side of Profile welded combination corresponding parallelism (mm) |

|||||||

|

≤ 1000 |

> 1000- 2000 |

> 2000- 4000 |

> 4000- 8000 |

> 8000- 12000 |

> 12000- 16000 |

> 16000- 20000 |

> 20000 |

|

| A | ≤1.5 | ≤2.0 | ≤3.0 | ≤4.0 | ≤5.0 | ≤6.0 | ≤7.0 | ≤8.0 |

| B | ≤3.0 | ≤4.5 | ≤6.0 | ≤8.0 | ≤10.0 | ≤12.0 | ≤14.0 | ≤16.0 |

| C | ≤5.5 | ≤9.0 | ≤11.0 | ≤16.0 | ≤20.0 | ≤22.0 | ≤25.0 | ≤25.0 |

| D | ≤9.0 | ≤14.0 | ≤18.0 | ≤26.0 | ≤32.0 | ≤36.0 | ≤40.0 | ≤40.0 |

| Alloy | Temper |

Wall thickness (mm) |

Mechanical Property |

BH(Brinell Hardness) HBW |

||||

|

Tensile Strength (MPa) |

Yield Strength (MPa) |

Elongation (%) | ||||||

| A | A50mm | |||||||

| Not less than | ||||||||

|

6005 , 6005A |

T4 | ≤25.00 | 180 | 90 | 15 | 13 | 50 | |

| T5 | ≤6.30 | 250 | 200 | - | 7 | - | ||

| >6.30-25.00 | 250 | 200 | 8 | 7 | - | |||

| T6 | Solid profile | ≤5.00 | 270 | 225 | - | 6 | 90 | |

|

>5.00- 10.00 |

260 | 215 | - | 6 | 85 | |||

|

>10.00- 25.00 |

250 | 200 | 8 | 6 | 85 | |||

| Hollow profile | ≤5.00 | 255 | 215 | - | 6 | 85 | ||

|

>5.00- 15.00 |

250 | 200 | 8 | 6 | 85 | |||

|

>15.00- 25.00 |

250 | 200 | 8 | - | - | |||

| 6061 | T4 | ≤25.00 | 180 | 110 | 15 | 13 | 65 | |

| T5 | ≤16.00 | 240 | 205 | 9 | 7 | - | ||

| T6 | ≤5.00 | 260 | 240 | - | 7 | 95 | ||

| >5.00- 25.00 | 260 | 240 | 10 | 8 | 95 | |||

| 6082 | T4 | ≤25.00 | 205 | 110 | 14 | 12 | 70 | |

| T5 | ≤5.00 | 270 | 230 | - | 6 | 90 | ||

| T6 | ≤5.00 | 290 | 250 | - | 6 | 95 | ||

| >5.00- 25.00 | 310 | 260 | 10 | 8 | 95 | |||

| Alloy | Temper |

Tensile Strength (MPa) |

Elongation A50mm (%) |

| Not less than | |||

|

6005 , 6005A |

T4 | 170 | 10 |

| T5,T6 | 200 | 7 | |

| 6061 | T4 | 170 | 13 |

| T5,T6 | 200 | 8 | |

| 6082 | T4 | 195 | 13 |

| T5,T6 | 230 | 7 | |