The aluminum Butt Weld pipe End Caps is a part of the container. According to the different geometric shapes, it can be divided into spherical, elliptical, dish, spherical crown, cone shell and flat cover, among which spherical, elliptical, dish, spherical crown is also collectively called the convex aluminum Butt Weld pipe End Caps Used in various container equipment, such as storage tanks, heat exchangers, towers, reactors, boilers and separation equipment, etc.

Aluminum head

Aluminum Cap Flange1

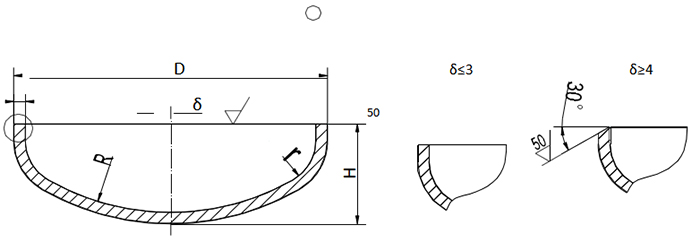

Aluminum Butt Weld pipe End Caps drawing

Markup example:

Aluminum pipe cap with nominal diameter DN=100, outer diameter D=110, wall thickness δ=4: pipe cap DN100 HT5079-84

The pressing process of aluminum end caps for tubing

This standard applies to pipe caps for pipes with PN≤1.0Mpa.

2 The type and size of the cap are specified in the following figure and table.

|

Nominal diameter DN |

D |

δ |

H |

R |

r |

Weight(Kg) |

|

15 |

18 |

2 |

14 |

15 |

3 |

0.009 |

|

20 |

25 |

2 |

18 |

20 |

4 |

0.015 |

|

25 |

30 |

2 |

23 |

24 |

5 |

0.022 |

|

40 |

45 |

2.5 |

28 |

36 |

7 |

0.038 |

|

50 |

55 |

3 |

36 |

44 |

8 |

0.103 |

|

65 |

70 |

3 |

40 |

56 |

11 |

0.157 |

|

80 |

90 |

4 |

45 |

72 |

14 |

0.346 |

|

100 |

110 |

4 |

52 |

88 |

17 |

0.517 |

|

125 |

133 |

4 |

60 |

107 |

20 |

0.70 |

|

150 |

158 |

4 |

68 |

126 |

24 |

1.10 |

|

200 |

208 |

4 |

94 |

166 |

32 |

2.11 |

|

250 |

260 |

5 |

110 |

208 |

40 |

4.50 |

|

300 |

312 |

6 |

130 |

250 |

48 |

8.53 |

|

350 |

362 |

6 |

140 |

290 |

56 |

12.14 |

|

400 |

412 |

6 |

152 |

330 |

63 |

16.55 |

|

500 |

516 |

8 |

170 |

413 |

80 |

14.84 |

|

600 |

630 |

8 |

200 |

504 |

97 |

84.66 |

|

700 |

720 |

8 |

224 |

576 |

110 |

119.7 |

|

800 |

820 |

10 |

250 |

656 |

126 |

207.2 |

|

900 |

920 |

10 |

272 |

736 |

142 |

334.3 |

|

1000 |

1020 |

12 |

298 |

816 |

157 |

510.3 |