In the pipeline system, the aluminum elbow is a pipe fitting that changes the direction of the pipeline. aluminum pipe elbows are divided into angles. There are three most commonly used aluminium elbows suppliers : Aluminum 45 Deg. Elbow and Aluminum 90 Degree Seamless Elbow Stockist,Aluminium DIN 180° Buttweld Elbow. In addition, according to engineering needs, they also include other abnormal angle elbows such as 60° and aluminum alloy elbows. Aluminum elbow connection methods include: direct welding (the most commonly used method) flange connection, hot melt connection, electrofusion connection, threaded connection and socket connection.

Aluminum elbow

The material of aluminium tube elbows can be divided into 1060 Aluminum Bending Radius Elbow, Aluminum 6061 Pipe Elbow, Aluminum Alloy 6063 Industrial Butt weld Elbow ,Aluminum Alloy 6082 Large Diameter Pipe Elbow, Aluminum 5083 Short Radius Elbow, etc.

The hardness of 1060 aluminum elbow is moderate, which can adapt to common processing conditions, such as bending, while the hardness of 6061 aluminum elbow is better, and it is widely used in places with high hardness requirements.

Characteristics, welding requirements and application scope of 5052 aluminum elbows

Features of 5052 series aluminum elbow:

Application range of 5052 aluminum elbow:

is often used in ships, ships, vehicle materials, automobile and aircraft plate welding parts, pressure vessels that require strict fire protection, refrigeration devices, television towers, drilling equipment, transportation equipment, missile components, armored subways, etc.

6061 aluminum elbow is a high-quality aluminum alloy product produced by heat treatment and pre-stretching process. Although its strength cannot be compared with 2XXX series or 7XXX series, it has many characteristics of magnesium and silicon alloys, and has excellent processing performance and excellent welding. Features and electroplating, good corrosion resistance, high toughness and no deformation after processing, compact material without defects and easy to polish, easy to color film, excellent oxidation effect and other excellent characteristics.

The main alloying elements of 6061 aluminum elbow are magnesium and silicon, and form Mg2Si phase. If it contains a certain amount of manganese and chromium, it can neutralize the bad effects of iron; sometimes a small amount of copper or zinc is added to increase the strength of the alloy without significantly reducing its corrosion resistance; there is a small amount of conductive materials In order to offset the adverse effects of titanium and iron on conductivity; zirconium or titanium can refine the grain and control the recrystallized structure; in order to improve the machinability, lead and bismuth can be added. Mg2Si is solid-dissolved in aluminum, which makes the alloy have artificial age hardening function. The main alloying elements in 6061 aluminum alloy are magnesium and silicon, which have medium strength, good corrosion resistance, weldability, and good oxidation effect.

Chemical composition The main chemical composition is (the mass fraction of each element)

Storage and maintenance methods of aluminum elbows:

1.The long-term storage of aluminum elbows should be checked regularly. The exposed surface of the aluminum elbow should be kept clean, cleaned of dirt, and stored neatly in a ventilated and dry place indoors. It is strictly forbidden to stack or store in the open air. Always keep the aluminum elbow dry and ventilated, keep the device clean and tidy, and store it according to the correct storage method.

2. Before installation, you must carefully check the various standards of the aluminum elbow, whether the diameter meets the use requirements, eliminate the defects caused by the transportation process, and eliminate the dirt of the aluminum elbow, make preparations before installation, and everything is ready.

3. When installing, the aluminum elbow can be directly installed on the pipeline according to the connection method, and the installation is carried out according to the used position. Under normal circumstances, it can be installed at any position in the pipeline, but it needs easy-to-operate maintenance. Note that the medium flow direction of the cut-off aluminum elbow should be upward from the vertical valve flap, and the aluminum elbow can only be installed horizontally. When installing the aluminum elbow, pay attention to the tightness to prevent leakage and affect the normal operation of the pipeline.

4. When using aluminum elbow ball valves, globe valves, and gate valves, they are only fully open or fully closed, and are not allowed to adjust the flow rate, so as to avoid erosion of the sealing surface and accelerated wear. There is an inverted sealing device in the gate valve and the upper threaded stop valve, and the handwheel is turned to the uppermost position and tightened to prevent the medium from leaking from the packing. Control caliber: aluminum elbow adopts standard (DN10-DN150), 3A/DF standard, standard (1/2-6), standard (Ф12.7-Ф152.4) for production, and produces aluminum bends of different quality and standards Heads, used in different fields, show different use values.

Aluminum elbow quality and use: the inside and outside of the product are treated with high-grade polishing equipment to meet the surface precision requirements; this product is suitable for stainless steel pipe systems in the industrial fields of dairy, food, beer, beverage, pharmaceuticals, cosmetics, etc.

Connection method: The connection method of the aluminum elbow adopts the welding butt welding clamp quick-fit threaded union type, which is easy to use;

External processing: Non-standard products can be processed according to user requirements with drawings and samples.

There are many maintenance methods for aluminum elbows of aluminum pipe fittings manufacturers, and they need to be used in accordance with a certain process method during use to ensure the service life and age of the aluminum elbows

International standards: DIN, ISO, 3A, SMS, BS, IDF, DS, BPE, etc. There are many standards for the production of aluminum elbows. It is necessary to carry out good production and design according to specific standards to produce aluminum elbows with good properties.

This standard applies to 90° seamless aluminum elbows with PN≤1.0Mpa.

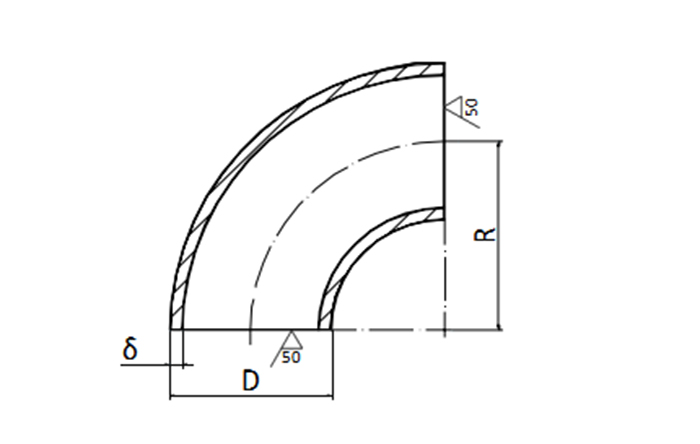

4 The type and size of the elbow are specified in the following figure and table:

Markup example:

90° seamless aluminum elbow with nominal diameter DN=80, outer diameter D=90, wall thickness δ=4mm. Seamless aluminum elbow DN80 HT5062-83

|

Nominal diameterDN |

Outer diameterD |

R |

δ |

weight (Kg) |

Nominal diameterDN |

Outer diameter D |

R |

δ |

weight (Kg) |

|

15 |

18 |

23 |

2 |

0.009 |

65 |

70 |

98 |

3 |

0.257 |

|

20 |

25 |

30 |

2.5 |

0.027 |

80 |

90 |

120 |

4 |

0.544 |

|

25 |

32 |

38 |

2.5 |

0.042 |

100 |

110 |

150 |

4 |

0.838 |

|

40 |

45 |

60 |

2.5 |

0.114 |

125 |

133 |

190 |

4 |

1.27 |

|

50 |

55 |

75 |

2.5 |

0.170 |

150 |

158 |

225 |

4 |

1.83 |

Welded aluminum elbow

This standard applies to connecting pipe aluminum elbows with PN≤0.25Mpa.

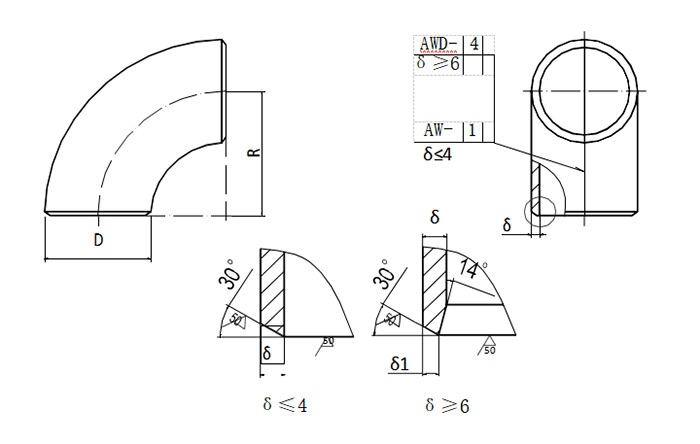

4 The type and size of the elbow are specified in the following figure and table

Markup example:

Welded aluminum elbow pipe with nominal diameter DN=200, pipe outer diameter D=206, wall thickness δ=3mm: elbow DN200 HT5068-87

|

Nominal diameterDN |

Outer diameter D |

R |

δ |

Weight (Kg) |

Nominal diameter DN |

Outer diameterD |

R |

δ |

δ1 |

Weight (Kg) |

|

100 |

105 |

120 |

2.5 |

0.404 |

400 |

408 |

420 |

4 |

/ |

9.93 |

|

125 |

131 |

140 |

3 |

0.716 |

500 |

508 |

520 |

6 |

4 |

24.5 |

|

150 |

156 |

165 |

3 |

0.991 |

600 |

630 |

630 |

6 |

4 |

32.01 |

|

200 |

206 |

215 |

3 |

1.73 |

700 |

720 |

720 |

8 |

4 |

54.3 |

|

250 |

258 |

265 |

4 |

3.92 |

800 |

820 |

820 |

8 |

4 |

71.05 |

|

300 |

308 |

315 |

4 |

5.04 |

900 |

920 |

920 |

8 |

5 |

89.75 |

|

350 |

358 |

365 |

4 |

6.83 |

1000 |

1020 |

1020 |

8 |

5 |

110.36 |

Note: The elbow with DN≤150mm is selected according to HT5062-83 "90° seamless aluminum elbow".

4Material: LF2

5 technical requirements

5.1 The material certificate must be attached to the elbow.

5.2 Remove welding bead and welding spatter.

5.3 The remaining technical requirements must meet the requirements of HT0008-83 "Technical Conditions for Manufacturing Welded Pipe Fittings".