aluminum pipe elbows are divided into angles. There are three most commonly used aluminium elbows suppliers : Aluminum 45 Deg. Elbow and Aluminum 90 Degree Seamless Elbow Stockist,Aluminium DIN 180° Buttweld Elbow. In addition, according to engineering needs, they also include other abnormal angle elbows such as 60° and aluminum alloy elbows. Aluminum elbow connection methods include: direct welding (the most commonly used method) flange connection, hot melt connection, electrofusion connection, threaded connection and socket connection.

Aluminum tee pipe

The material of aluminium tube elbows can be divided into 1060 Aluminum Bending Radius Elbow, Aluminum 6061 Pipe Elbow, Aluminum Alloy 6063 Industrial Butt weld Elbow ,Aluminum Alloy 6082 Large Diameter Pipe Elbow, Aluminum 5083 Short Radius Elbow, etc.

International standards: DIN, ISO, 3A, SMS, BS, IDF, DS, BPE, etc. There are many standards for the production of aluminum elbows. It is necessary to carry out good production and design according to specific standards to produce aluminum elbows with good properties.

This standard is applicable to pipe connection aluminum tee with PN≤1.0Mpa and DN≤150.

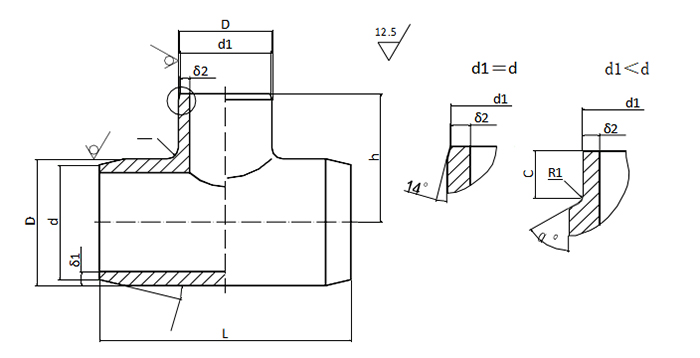

The structure type and main dimensions of the three links are specified in the following figure and table.

Markup example:

Tee with a straight pipe with a nominal diameter of 300 and a branch pipe with a nominal diameter of 200: Tee 300/200 HT5076-84

measurement unit:mm

|

Nominal diameter DN |

structure size |

Weight (Kg) |

|||||||||||

|

Straight tube |

Branch pipe |

d |

d1 |

D |

L |

h |

R |

δ1 |

δ2 |

R1 |

C |

α° |

|

|

15 |

15 |

18 |

18 |

20 |

50 |

25 |

2 |

2 |

2 |

- |

- |

- |

0.006 |

|

20 |

15 |

25 |

18 |

27 |

64 |

32 |

3 |

2.5 |

8 |

10 |

50 |

0.059 |

|

|

20 |

25 |

2.5 |

- |

- |

- |

0.049 |

|||||||

|

25 |

15 |

30 |

18 |

32 |

76 |

38 |

2 |

8 |

12 |

50 |

0.094 |

||

|

20 |

25 |

2.5 |

15 |

0.082 |

|||||||||

|

25 |

30 |

- |

- |

- |

0.072 |

||||||||

|

2.5 |

15 |

45 |

18 |

47 |

114 |

57 |

4 |

2 |

8 |

15 |

50 |

0.287 |

|

|

20 |

25 |

2.5 |

18 |

0.269 |

|||||||||

|

25 |

30 |

21 |

0.253 |

||||||||||

|

40 |

45 |

- |

- |

- |

0.188 |

||||||||

|

50 |

20 |

55 |

25 |

57 |

128 |

64 |

6 |

3 |

8 |

12 |

50 |

0.436 |

|

|

25 |

30 |

15 |

0.419 |

||||||||||

|

40 |

45 |

21 |

0.350 |

||||||||||

|

50 |

55 |

- |

- |

- |

0.290 |

||||||||

|

65 |

25 |

70 |

30 |

72 |

148 |

74 |

8 |

8 |

10 |

50 |

0.696 |

||

|

40 |

45 |

12 |

0.623 |

||||||||||

|

50 |

55 |

15 |

0.559 |

||||||||||

|

65 |

70 |

3 |

- |

- |

- |

0.424 |

|||||||

|

80 |

25 |

90 |

30 |

93 |

172 |

86 |

10 |

4 |

2.5 |

10 |

10 |

50 |

1.35 |

|

40 |

45 |

12 |

1.28 |

||||||||||

|

50 |

55 |

10 |

60 |

1.21 |

|||||||||

|

65 |

70 |

3 |

15 |

1.07 |

|||||||||

|

80 |

90 |

4 |

- |

- |

- |

0.85 |

|||||||

|

100 |

25 |

110 |

30 |

114 |

210 |

105 |

12 |

2.5 |

10 |

10 |

60 |

2.38 |

|

|

40 |

45 |

15 |

2.29 |

||||||||||

|

50 |

55 |

10 |

50 |

2.21 |

|||||||||

|

65 |

70 |

3 |

15 |

2.04 |

|||||||||

|

80 |

90 |

4 |

21 |

1.77 |

|||||||||

|

100 |

110 |

- |

- |

- |

1.4 |

||||||||

|

125 |

25 |

133 |

30 |

137 |

244 |

122 |

14 |

2.5 |

10 |

10 |

65 |

3.68 |

|

|

40 |

45 |

60 |

3.57 |

||||||||||

|

50 |

55 |

12 |

3.47 |

||||||||||

|

65 |

70 |

3 |

10 |

50 |

3.29 |

||||||||

|

80 |

90 |

4 |

15 |

2.99 |

|||||||||

|

100 |

110 |

25 |

2.58 |

||||||||||

|

125 |

133 |

- |

- |

- |

1.98 |

||||||||

|

150 |

25 |

158 |

30 |

162 |

286 |

143 |

16 |

2.5 |

10 |

12 |

65 |

5.57 |

|

|

40 |

45 |

15 |

5.45 |

||||||||||

|

50 |

55 |

18 |

5.35 |

||||||||||

|

65 |

70 |

3 |

21 |

5.13 |

|||||||||

|

80 |

90 |

4 |

12 |

50 |

4.78 |

||||||||

|

100 |

110 |

18 |

4.30 |

||||||||||

|

125 |

133 |

25 |

3.55 |

||||||||||

|

150 |

158 |

- |

- |

- |

2.73 |

||||||||

6Material: LF2

3 Machining unmarked dimensional tolerances shall be in accordance with HT0017-83 "Unmarked Dimensional Tolerance and Geometric Tolerance of Machining Elements".

4 The tee shall not have cracks, pores, slag inclusions and other defects that affect the strength and tightness.

5 The surface marking is in accordance with the relevant provisions of Article 11 of HT0008-83 "Technical Conditions for Manufacturing Welded Pipe Fittings".

Aluminum tees are widely used in various industries, such as automobiles, ships, aerospace, aviation, electrical appliances, agriculture, electromechanical, household appliances, etc. The following is an introduction to the installation and preservation of aluminum tees: