Properties such as conductivity, strength and corrosion resistance of 2024 aluminum flat bars all determine how they are used. Here, we cover aluminum alloy 2024, which is derived from the 2xxx series of aluminum alloys or aluminum alloys with copper as the main alloying element.

In 2024 aluminum flat bar, the alloying elements used increase its strength significantly. This is because the total elemental percentages of added copper (Cu), magnesium (Mg) and manganese (Mn) are 6.5% – Cu-4.4%, Mg-1.5% and Mn-0.6%. However, the strength increase provided by the high percentage of copper does reduce its corrosion resistance.

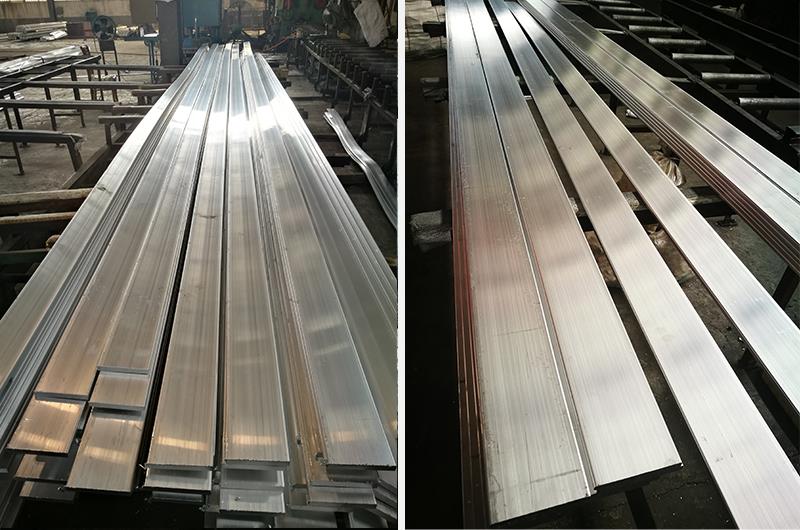

Aluminum alloy 2024 has good machinability and is easy to machine, so it can be extruded, cold worked and cut as needed.

As mentioned above, the base 2024 aluminum flat bar is more susceptible to corrosion than most other aluminum alloys. This problem can be solved by cladding the 2024 aluminum flat bar sheet with a more corrosion resistant aluminum sheet product. The final product has the strength of a 2024 aluminum flat bar with the corrosion resistance of other alloys, but is still lightweight. The cladding may be a high-purity aluminum alloy such as 1100 or 3003.

Heat treatment is typically used on 202 aluminum alloys as it can be used on other aluminum alloys such as the 2xxx, 6xxx and 7xxx series. During this process, the alloy is heated to a set temperature that allows the alloying elements to be homogenized or mixed into the base metal. The metal is then solution heat treated, in which the metal is quenched in a solution that locks the element in place. As the workpiece cools, copper atoms and other elements precipitate out of solution. This process increases the strength of the alloy through a process called aging, in which the compound interacts with the aluminum's microstructure. Depending on the implementation of aging and solution heat treatment, 2024 aluminum may have specific temper designations such as 2024-T3, 2024-T351, and 2024-T4.

Aluminum alloys, including 2024 aluminum sheet, can be specified based on the specific mechanical properties they possess. Some of the important properties of 2024 include yield strength, ultimate strength, fatigue strength, shear strength, shear modulus, and elastic modulus.

Yield strength is the maximum stress that a material can withstand without permanent deformation. Ultimate strength is the maximum stress that certain materials can withstand before the material breaks. The yield and ultimate strengths of 2024 aluminum are as high as 47,000 psi and 68,000 psi, respectively, making this alloy ideal for certain high-strength structural applications.

Aluminum alloy 2024 has a moderate shear strength value of 41,000 psi. With this level of shear strength, you can find 2024 in shear pins that require aluminum rather than steel. In aerospace applications, fatigue strength is an important measure of 2024 aluminum flat bar and other materials. Aircraft components are subjected to repeated stresses involved in landing and take-off activities. These stresses do not initially cause deformation. However, when they repeat over a period of time, they can weaken the alloy microscopically, leading to macroscopic weakening. Fatigue strength measures the resistance of a material to fracture under repeated stress. 2024 aluminum flat bar (including 2A12 aluminum plate form) has a fatigue strength of 20,000 psi calculated for 500 million loading cycles below the yield point.

Shear modulus and elastic modulus are properties of materials that indicate their elasticity to permanent deformation. Aluminum alloy 2024 has a shear modulus of 4,060 ksi and an elastic modulus of 10,600 ksi, greater than the same properties of 7075 aluminum.

2024 type aluminum alloy has high strength, good workability, excellent machinability and ability to accept cladding to make it corrosion resistant. All of these properties combine to make it an excellent choice for applications involving aircraft and vehicles. Many industries use the aluminum 22024 alloy. Some common applications for this alloy include cylinders, truck wheels, pistons, gears, hydraulic manifold blocks, and impact machinery.

Because of this high strength and fatigue resistance, 2024 aluminum flat bars are commonly used in structural applications involving aircraft. While 7075 aluminum alloy is well-suited for applications involving high stress and strain resistance, aluminum alloy 22024 is highly resistant to cyclic fatigue. It's also a stronger aluminum alloy than 6061, but less versatile.