The difference between 6061 aluminum alloy and 6063 aluminum alloy aluminum alloy

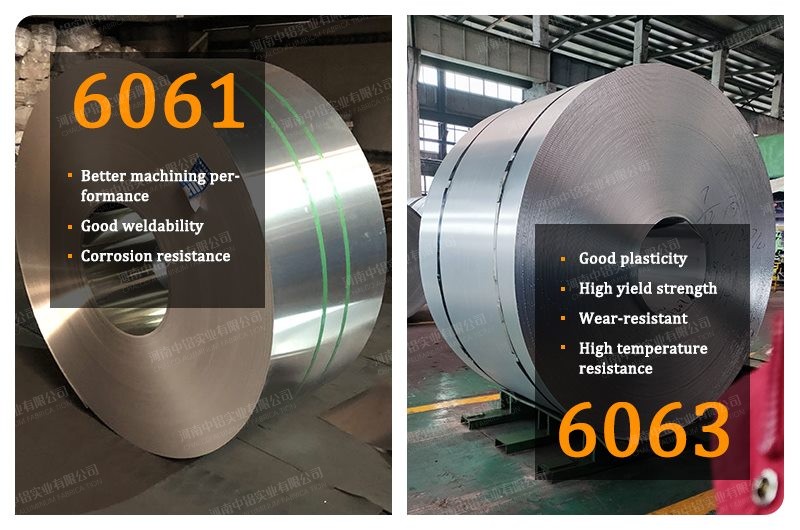

The difference between 6061 aluminum alloy and 6063 aluminum alloy: different chemical composition, mechanical properties, scope of use, heat treatment process. 6061-T651 is the main alloy of 6061 aluminum alloy. Although its strength cannot be compared with 2XXX series or 7XXX series, its magnesium and silicon alloys have many characteristics, and it has excellent processing performance, excellent welding characteristics, electroplating and good resistance. Corrosion, high toughness and no deformation after processing, dense material without defects and easy to polish, easy to color film, excellent oxidation effect and other excellent characteristics. 6063 aluminum alloy is a heat-treatable strengthening alloy with moderate strength in the AL-Mg-Si series. Mg and Si are the main alloying elements. The main work of optimizing the chemical composition is to determine the percentage content of Mg and Si (mass fraction, the same below) .

6063 aluminum alloy

6061 aluminum alloy is no longer cold processed after solid solution heat treatment, and can be naturally aged (T4 state), or directly artificially aged, that is, T6 state, which has a large deformation coefficient, high hardness, and is not easy to control; while 6063 aluminum alloy After high temperature molding, it is cooled, that is, the quenching process. Generally, the cooling method of air cooling is adopted, and then it is artificially aged, that is, the T5 state. It can eliminate the internal stress of industrial aluminum profiles to the greatest extent, the deformation coefficient is small, the hardness is not so high, it will not break easily, and the mechanical properties are stronger, but 6063 aluminum alloy also adopts the T6 treatment method, and its deformation coefficient will also be It becomes larger, the hardness is higher, and the fracture phenomenon is more likely to occur than T5.