It's well known that

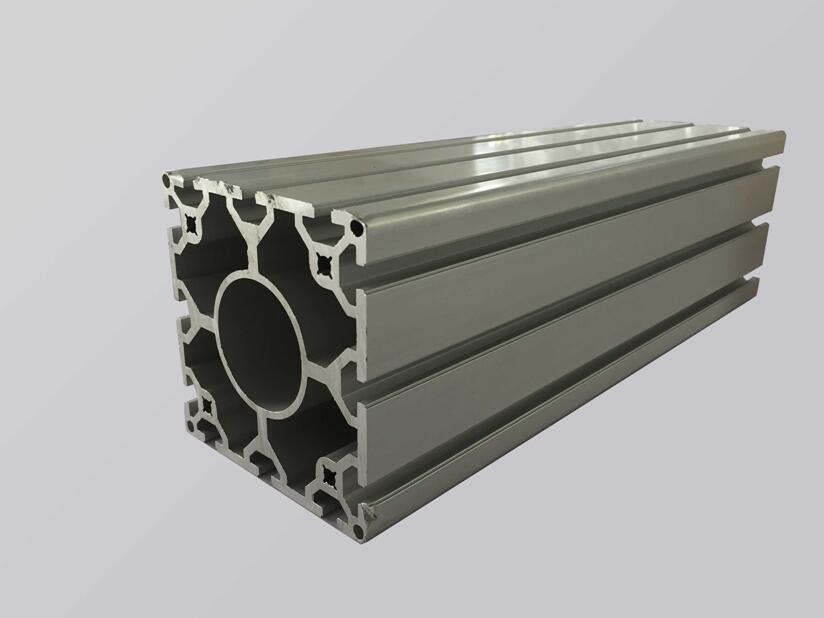

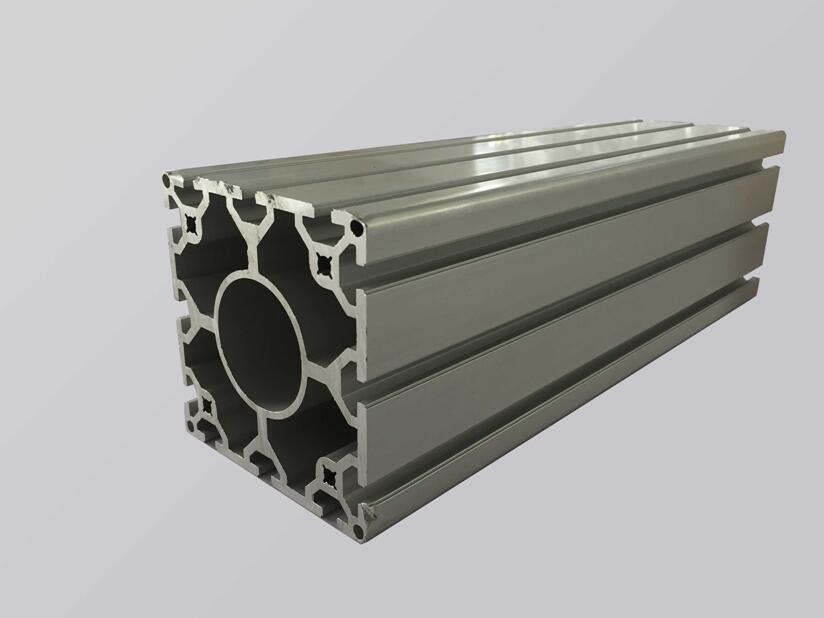

Aluminum profile extrusion china surfaces are particularly vulnerable to scratches so how do you avoid them?

A Brief Analysis of the elimination methods of surface abrasions of

Aluminum profile extrusion china :

(1) stretch

Aluminum profile extrusion china must be one by one, sawn

Aluminum profile extrusion china can not be stacked two layers and above the

Aluminum profile extrusion china.

(2) The cold bed, feeding table, sawing table and other platform

Aluminum profile extrusion china should not be piled up over full, profiles keep a distance from each other, after the staff early operation, to prevent the friction and collision between

Aluminum profile extrusion china .

(3) the extrusion die hole

Aluminum profile extrusion china if the speed is not uniform, uneven length, try to use the die adjustment.More than 3 hole

Aluminum profile extrusion china of uneven length, take graphite plate (high temperature felt) separate method, do not make the porous profiles friction each other, causing scratch.

(4) Sawing, framing, packaging and other procedures to produce aluminum chips every time (root, branch) blow clean, can be operated again.

(5) before the mold assembly must check: die empty knife, support cushion hole, special cushion hole can meet the requirements of profile material size, whether paste white aluminum, there should be early clearance.To prevent the mold pad from sticking to aluminum, some graphite oil can be applied when the pad temperature reaches 150 degrees or so.