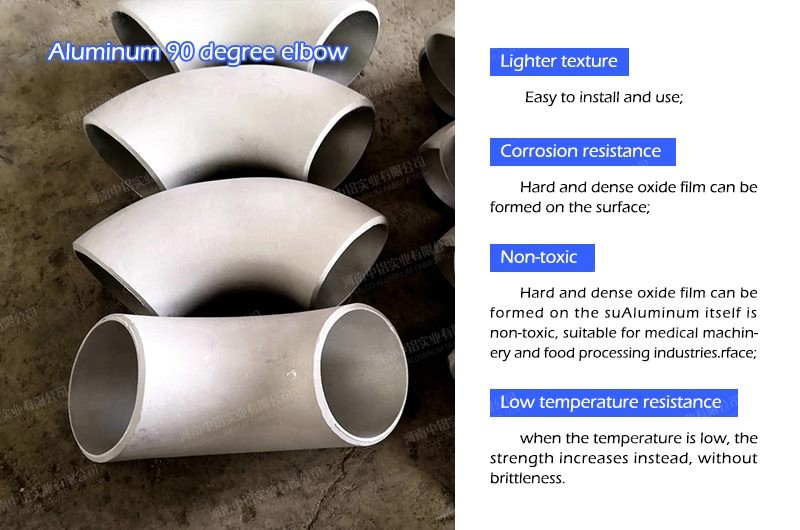

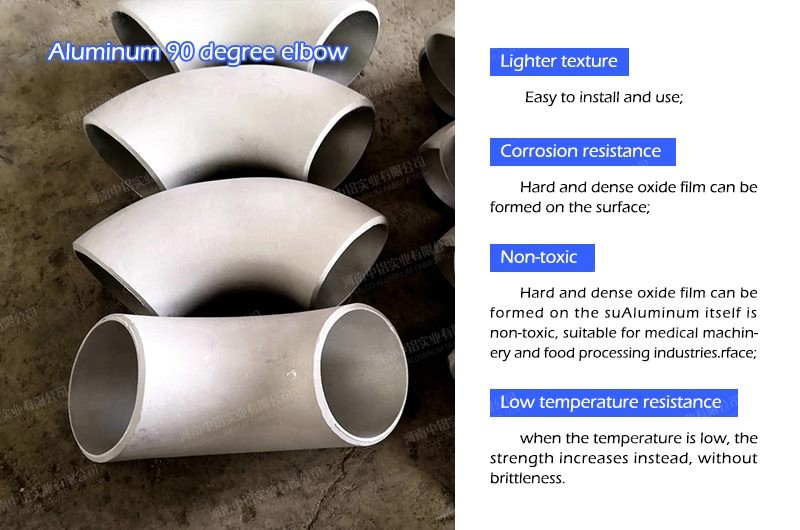

Introduction of aluminum 90 degree elbow

The aluminum alloy elbow is an elbow made of an aluminum alloy material. It is the same as other elbows, but it is only used in a specific place for the connection of the turning of the pipe. The aluminum alloy elbow material is about 5052, 5083, 6061, 6062, 1060, which are pure aluminum 90 degree elbow, and the aluminum content is relatively high. The aluminum alloy elbows are divided into aluminum 90 degree elbow, aluminum 45 degree elbow, aluminum 60 degree elbow, aluminum 180 degree elbow. Etc., other angles can be processed and customized according to customer requirements, but these are the more common angles of use.

aluminum 90 degree elbow, compared with other carbon steel elbows, alloy elbows have some advantages, such as lighter texture; easy to install and use; corrosion resistance, the surface can generate a hard and dense oxide film, and many substances do not produce it. Degenerate effect; no magnetism. Non-toxic: Aluminum itself is not toxic, so aluminum flanges are more suitable for medical machinery and food processing industries. Low temperature resistance: When the temperature of aluminum flange is low, its strength increases without brittleness, so it is an ideal low temperature device material.

The following introduces the maintenance and maintenance methods and precautions of aluminum 90 degree elbow, a manufacturer of aluminum pipe fittings:

-

1. The aluminum 90 degree elbow that has been stored for a long time should be checked regularly, and the frequently exposed processing surface must be kept clean, and it is strictly forbidden to pile up or store in the open air to remove dirt. , Store neatly in a ventilated and dry place indoors, keep the aluminum 90 degree elbow dry and ventilated, keep the appliance clean and tidy, and store it according to the correct storage method.

-

2. Before installation, you must carefully check the various standards of the aluminum 90 degree elbow, whether the caliber meets the requirements for use, eliminate the defects caused by the transportation process, and eliminate the fouling of the aluminum 90 degree elbow, make preparations before installation, and everything is ready.

-

3. During installation, the aluminum 90 degree elbow can be directly installed on the pipeline according to the connection method, and installed according to the position of use. Under normal circumstances, it can be installed at any position of the pipeline, but it is necessary to facilitate the operation and maintenance. Note that the medium flow direction of the cut-off aluminum 90 degree elbow should be upward from the bottom of the vertical valve disc, and the aluminum 90 degree elbow can only be installed horizontally. When installing aluminum 90 degree elbow, attention should be paid to the tightness to prevent leakage and affect the normal operation of the pipeline.

-

4. When the ball valve, globe valve and gate valve of aluminum 90 degree elbow are used, they are only fully open or fully closed, and are not allowed to be used to adjust the flow, so as to avoid erosion of the sealing surface and accelerated wear. There are reverse sealing devices in the gate valve and the upper threaded globe valve. The handwheel is turned to the upper position and tightened to prevent the medium from leaking from the packing. Control caliber: aluminum 90 degree elbow adopts standard (DN10-DN150), 3A/DF standard, standard (1/2-6), standard (Ф12.7-Ф152.4) for production to produce aluminum of different quality and standards 90 degree elbow, used in different fields, showing different use values.